while in the microscopic realm where by innovation thrives, an invisible menace looms significant: particulate contamination. For industries like semiconductor production and pharmaceutical output, where precision and purity are not simply goals but absolute necessities, the existence of even just one stray particle can spell catastrophe. This fact areas immense stress on suppliers not simply to accomplish unparalleled cleanliness but additionally to display unwavering environmental obligation. The solution lies in refined checking, online particle counter wholesale supported by Sophisticated particle counter makers, performing as vigilant guardians to make sure that procedures remain pristine, solutions are Protected, and our planet is revered. This deep dive explores the multifaceted troubles and technological progress, together with chopping-edge particle counting answers, shaping the landscape of clear monitoring in these essential sectors. the trendy globe operates on semiconductors, as well as the development of those intricate chips is often a marvel of engineering. equally, our wellbeing and wellbeing generally depend upon pharmaceuticals created with exacting benchmarks. What links these seemingly disparate fields is surely an Extraordinary sensitivity to contamination. Understanding this url, along with the pivotal contributions of particle counter makers, is crucial for appreciating the crucial purpose of State-of-the-art particle checking.

Table of contents:

sector Perspectives: The common demand from customers for Purity

Environmental and Compliance Angles: further than product or service high-quality

checking know-how: The Evolution of Precision

client worth: The Tangible advantages of Vigilance

marketplace Perspectives: The Universal need for Purity

when particular demands vary, the fundamental will need for ultra-clear environments is a common thread across large-technological know-how and daily life science sectors.

Semiconductor Manufacturing: The Nanoscale Battleground

The semiconductor industry operates over a scale almost incomprehensible to the bare eye.晶圆厂 (wafer fabs) are the heart of this globe, manufacturing the silicon wafers that develop into microprocessors, memory chips, and various important elements. The manufacturing course of action will involve many hundreds of actions, many of which use extremely-superior purity (UHP) gases like nitrogen (N₂), argon (Ar), helium (He), hydrogen (H₂), carbon dioxide (CO₂), and thoroughly clean dry air (CDA). Even moment particulate contamination in these gases may result in wafer defects, rendering whole batches of chips worthless. just one 0.one-micrometer particle landing on the crucial layer through photolithography might cause a brief circuit or an open up circuit, resulting in significant fiscal losses and manufacturing delays. Therefore, the semiconductor cleanroom surroundings and also the purity of system gases are issue to by far the most stringent controls, often demanding checking all the way down to the nanometer degree. The key word here is semiconductor cleanroom, plus the obstacle is gas particle contamination leading to wafer defects.

Pharmaceutical output: Safeguarding wellness, Ensuring Compliance

In pharmaceutical manufacturing, specially for sterile products like injectables, ophthalmics, and biologics, the stakes are human lives. great Manufacturing techniques (GMP) are not merely guidelines but legally binding rules that dictate the conditions less than which medication are created. Pharmaceutical air quality and the purity of system gases are paramount. Contamination by microorganisms or inert particles can compromise drug efficacy, trigger adverse client reactions, or perhaps bring on deadly outcomes. Cleanroom classifications, including those outlined by ISO 14644-one and GMP Annex 1, established rigid limitations on airborne particle concentrations. Gases used in blanketing, sparging, or as propellants must be free from contaminants. UHP gasoline protection and demanding particle Management are Therefore non-negotiable for GMP compliance.

health-related machine production: Precision and Biocompatibility

The creation of healthcare equipment, In particular implantable products like pacemakers, stents, or artificial joints, and demanding surgical equipment, also demands extremely clean environments. Particulate contamination on the floor of the implant can lead to inflammation, an infection, or system failure once inside the human system. brands ought to adhere to criteria like ISO 13485, which emphasizes high-quality management techniques for clinical gadgets. Cleanrooms built to ISO 13485 cleanroom benchmarks and using monitored, clean up gases are important to avoid clinical gadget fuel checking for particulate contamination that would compromise affected individual security.

Laboratories and R&D Centers: The hunt for correct knowledge

over and above massive-scale producing, study and improvement laboratories are the crucibles of innovation. significant-precision experiments, whether in products science, nanotechnology, or biomedical exploration, depend on incredibly pure gases and controlled environments. Any undesired particles can interfere with sensitive analytical devices, skew test success, or invalidate full study initiatives. A trusted lab gasoline particle counter is essential to mitigate contamination possibility and make sure the integrity of scientific discovery.

Environmental and Compliance Angles: further than item top quality

The drive for cleanliness extends further than mere product or service top quality; it intertwines with broader environmental obligations and regulatory compliance, shaping how modern industries function.

Adherence to GMP/ISO specifications: The Regulatory Backbone

Compliance with requirements like ISO 14644 for cleanrooms and controlled environments, and GMP for pharmaceuticals, is basic. These standards explicitly define demands for particle checking. constant ISO14644 checking and making certain GMP thoroughly clean fuel are not only most effective techniques but auditable necessities. Failure to comply may result in products recalls, facility shutdowns, and significant reputational harm. a sturdy particle counting procedure delivers the data to reveal ongoing adherence.

Carbon Footprint Management: The Sustainable critical

Environmental sustainability can be an significantly critical worry. While cleanroom functions are Electrical power-intense, helpful particle checking contributes indirectly but noticeably to minimizing the carbon footprint in cleanrooms. By reducing item defects and rework brought on by contamination, manufacturers minimize squander, conserve raw components, and decreased Electricity usage associated with remanufacturing. This sustainable clean approach is often a crucial ingredient of dependable production.

ESG Audit assistance: Demonstrating motivation

Environmental, Social, and Governance (ESG) criteria have gotten essential indicators for traders and stakeholders. information-driven, quantifiable proof of environmental stewardship is vital. steady particle monitoring systems that log knowledge provide tangible ESG compliance metrics. This demonstrates a determination to eco-friendly manufacturing metrics and proactive environmental management, improving company name and investor self confidence.

Minimizing Emissions: preserving the broader atmosphere

successful particle Regulate with the source, in just process gases and cleanroom environments, incorporates a direct effect on air emission Command. through the use of Highly developed inline particle counters to discover and deal with contamination issues in advance of they escalate, companies can decrease the load on downstream filtration devices. This not just prolongs filter existence but also minimizes the probable for zero particle discharge of dangerous particulates into your exterior setting, contributing to cleaner air beyond the ability partitions.

checking Technology: The Evolution of Precision

the opportunity to meet these stringent calls for hinges over the sophistication of checking engineering. common methods are providing method to a lot more advanced, built-in alternatives.

Inline checking vs. Grab Sampling: The Real-Time benefit

Historically, particle counting often relied on seize sampling, the place a sample of gas or air is taken periodically and analyzed offline. when handy, this process gives merely a snapshot and might skip intermittent contamination activities. Inline gas checking, wherever sensors are built-in specifically into your gasoline line or system natural environment, features a big step forward. it offers real-time particle information, allowing for speedy detection of excursions from appropriate limits. This proactive strategy allows immediate response to circumvent prevalent contamination, a crucial advantage in excess of reactive place checks.

Multi-Gas Compatibility: flexibility in Detection

modern-day producing procedures benefit from a various array of gases. A truly helpful particle monitoring technique have to exhibit UHP gasoline detection abilities across various gasoline kinds, together with N₂, CDA, CO₂, Ar, He, and H₂. This fuel compatibility sensor style makes certain that an individual type of instrument is usually deployed throughout a variety of details in a very facility, simplifying operations, teaching, and servicing, even though offering constant and reliable info regardless of the gasoline matrix.

Nanoparticle Detection capacity: observing the extremely-modest

As semiconductor element sizes shrink and pharmaceutical formulations develop into more complicated, the impact of even smaller sized particles grows. The ability to detect particles in the sub-micron checking degree, for instance, 0.oneμm as well as scaled-down, is now vital. Advanced nanoparticle counter technological innovation pushes the boundaries of detection, giving insights into contamination resources that were previously invisible.

info Logging and Traceability: The Power of knowledge

In regulated environments, data is king. fashionable particle counters are equipped with robust particle traceability functions, together with huge-ability details storage and straightforward fuel good quality info logging export by using USB or community connections. This thorough details logging is vital for development Assessment, method optimization, troubleshooting contamination occasions, and providing documented proof through audits.

buyer price: The Tangible great things about Vigilance

buying Innovative particle monitoring is not an expense but a strategic investment that provides substantial returns by means of enhanced operational effectiveness and possibility mitigation.

reducing Contamination chance: Proactive avoidance

the first price of genuine-time particle checking is contamination risk prevention. By detecting deviations from baseline particle ranges quickly, operators can intervene right before a minor difficulty escalates into An important contamination event, conserving entire merchandise batches from staying compromised.

Improving solution Yield and high-quality: The Bottom Line

For semiconductor and pharmaceutical manufacturers, yield enhancement is a constant pursuit. By ensuring the purity of course of action gases as well as the cleanliness of your production ecosystem, defect Handle turns into more effective. This specifically interprets to larger products yields, diminished scrap charges, and important Expense cost savings.

improving model believability and believe in: the industry Differentiator

A demonstrable motivation to the highest benchmarks of purity and environmental responsibility substantially boosts cleanroom track record. Customers, especially in B2B associations, achieve self esteem while in the dependability and top quality of the supply chain. This center on good quality Management might be a powerful market place differentiator.

decreasing upkeep and Scrapping expenditures: Operational Excellence

Contaminants not merely spoil merchandise but may hurt delicate manufacturing devices. By protecting cleaner system streams, firms can lower servicing price savings connected with Repeated cleaning, calibration, and replacement of fouled elements. This proactive strategy also results in considerably less tools safety associated downtime, optimizing operational uptime and reducing squander.

The path to immaculate generation environments and liable producing is paved with Innovative technological know-how in addition to a relentless commitment to purity. As industries keep on to push the boundaries of innovation, the job of advanced monitoring methods, especially All those featuring inline, actual-time facts for high purity gases, will become at any time a lot more essential. providers that present these applications are critical companions Within this pursuit.

By way of example, seeking out highly regarded particle counter manufacturers who concentrate on instruments just like a large Purity gasoline Particle Counter is key. answers from companies which include Lasensor, with their inline higher-pressure UHP gas particle counters, exemplify the type of technologies that empowers industries. Their units are engineered to deliver the precision, dependability, and actual-time info critical for navigating the sophisticated issues of particle Command in crucial environments. Whether sourcing one device or Discovering choices for an on the web particle counter wholesale arrangement for greater deployments, partnering with a experienced vendor ensures that the guardians of purity are normally on view.

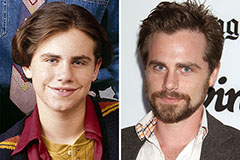

Rider Strong Then & Now!

Rider Strong Then & Now! Susan Dey Then & Now!

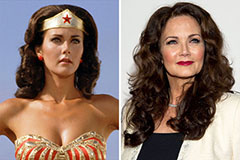

Susan Dey Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Kane Then & Now!

Kane Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!